🚀 We are Hiring! Join our team and build something amazing. Join Us!

in the global footwear industry

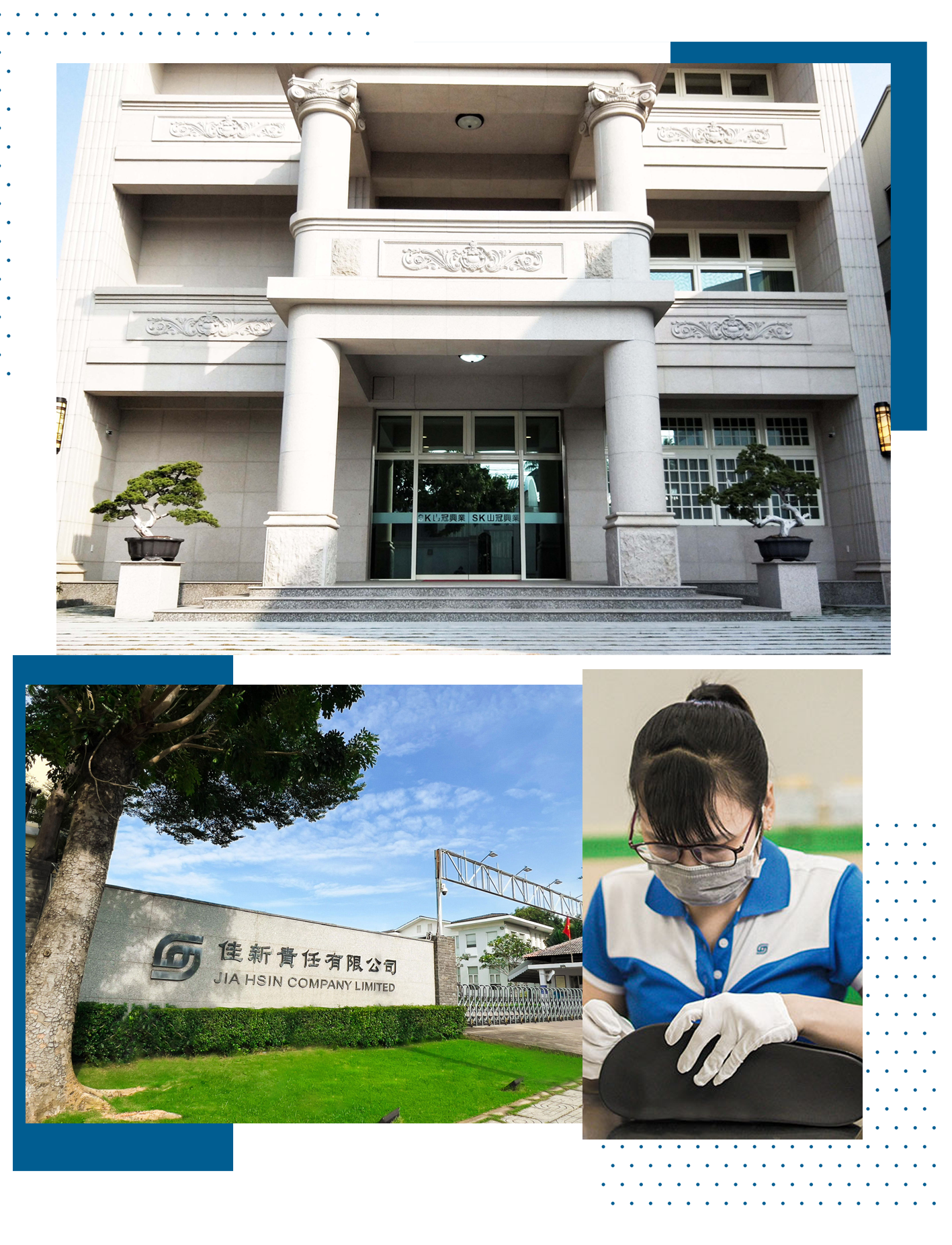

We are committed to positioning ourselves as the foremost, reliable, and most joyful enterprise in the global footwear industry. As we embark on this journey, our emphasis extends beyond mere business success; we strive to enrich the life experiences of all individuals who engage in our business. By combining cutting-edge innovation, unwavering trustworthiness, and a commitment to fostering happiness, we aim to redefine the standards of excellence in the footwear sector.

The factory was Established at the end of 2008 and officially threw in production since June 2009. It spans an area of approximately 13.4 hectares. We currently produce 60 million EVA foam beach sandals annually, employing 9,000 workers. All our products are exported to numerous global markets through renowned brands such as adidas, Puma, Rockport, The North Face, Timberland, Reef, New Balance, Under Armour, Columbia, and more.

Explore More